Changing Competitive Demands from 20th to 21st Century

Acceleration of change has introduced new competitive requirements in the 21st century. It involves multiple criteria for effectiveness, which are sometimes contradictory. This evolution is as follows:

The early 20th century in 1911, saw the advent of the Taylor school of Scientific Management. It moved the craftsmanship based manufacturing to mass production. This was based on specialization through the division of labor for maximizing internal efficiencies. With the success of mass production systems in the Second World War, the 1950s and 1960s saw Efficiency / Productivity as the most important criterion for the competitiveness of organizations in the American and European based enterprises. This development was dictated by a major change in mass manufacturing technologies. Productivity in terms of quantity was the prime objective. It meant doing more of the same things: by specialization in well-defined market segments. Management wanted to exploit economies of scale or repetition effects. The so-called learning curve effect introduced by Arrow, resulted in accumulated experience, with decreasing per-unit cost.

Learning by doing was possible as most markets were ‘sellers’ markets, that seemed to have unlimited growth potential. Efficiency was largely obtained through standardization. The organization, which could standardize most of its processes, would outperform its competitors. Management tried to optimize everything inside the organization and ignored the external competitive environment. Standardization resulted in a separation of thinking and doing. Attempts were made to achieve strong control and coordination in order to assure stability. The closed system approach resulted in control-oriented organizations, with complex structures, simple routines, and monotonous tasks.

The 1970s brought about a dramatic change in global management thought based on Statistical Thinking and Lean Thinking. It was ushered in by the Japanese corporations. They translated this thinking into the Total Quality concept rooted in practice, with cultural ramifications. They successfully deployed it strategically not only within their organizations but across the entire value chain. It resulted in driving cost competitiveness and product differentiation simultaneously. Companies such as Toyota, Honda, Sony, etc. strongly positioned themselves in the global automotive and electronics markets, based on their learning’s from the American quality gurus like Dr. Deming, Dr. Juran, and their own homegrown experts like Dr. Ishikawa. Hence, now Quality became an additional important criterion.

This development compelled the organizations in the US and Europe to shift their product view of quality (small q) and adopt a more holistic and organizational view of quality (Big Q) leading to the genesis of Total Quality Management, TQM. However, the quality-based strategies were limited by the inherent rigidities of the linear model of the strategic planning process of most corporations, hence lacking the dynamic fit under fast-changing environments. It worked well only when the environments were stable, and the future was predictable. The case of Motorola, the first Baldrige winner in the late 1980’s, illustrates the issue of dynamic fit, which eventually led to their fall from market leadership.

The Big Q view helped organizations enhance their customer focus by proactively managing the customer-supplier relationships. This enhanced their capacities to interpret the change signals coming from the competitive environment, particularly from customers to stimulate innovation. The successful organizations of the late 20th century such as Toyota, Honda, GE, Dupont, Boeing, Siemens, ABB, Bank of America, etc. leveraged quality strategically for driving growth. The did it by deployment across their complete value chain beyond manufacturing, including applications in services. Simultaneously the shift from sellers to a buyer’s market created more choice from the enhanced competition; with a multidimensional set of preferences that behaved dynamically as shown by Dr. Kano in his model of attractive quality. This shift in global management thought, required very creative and innovative fulfillment capabilities.

From the 1990s through the end of the 20th century and the first decade of the new century, saw the onset and the acceleration of globalization, where the markets became more open as a result of decreased entry barriers and intensive international competition. There was no more elasticity or slack possible within the efficiency norms. The only way to distinguish an organization from another was ‘excellence’. Organizational excellence frameworks based on the principles of TQM gained popularity, as they enhanced competitiveness by helping them to leverage synergies. This helped them to deal with complexity, in a growing world of collaboration.

21st Century: Age of Hyper-competition, Uncertainty & Turbulence

Practitioners from across different industries are in agreement with experience, that high productivity and efficiency-driven low cost with high quality, are no longer enough to guarantee success. It is insufficient and sometimes loses relevance in the face of accelerated competitive change, technological disruptions, uncertainty, and turbulence in the environment. To counter, companies are increasingly concentrating on flexibility as a way to achieve new forms of competitive advantage. As changing circumstances call for different responses, a new approach to managing quality and innovation is called for, by incorporating a new trend in global management thought called flexibility thinking introduced by Dr. Volberda in 1998 which is realizing its potential in practice. Thus it becomes an imperative now to counter change, by broadening the response away from just the narrow pursuit of efficiency and striving for perfection.

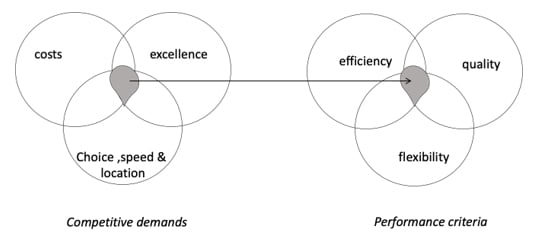

Exhibit 1.0 illustrates the accumulation of competing demands and conflicting performance criteria emerging from the ‘new normal’ in the post-pandemic era, where ‘location’ for example is an added variable. This is due to the safety needs of customers and fuelled by a technology-based, low touch economy. This additional requirement from customers is emerging from the current pandemic situation, where non-contact transactions are required, hence safety and quality of logistics is now a critical factor to avoid contamination and transmission. As a result, we are already experiencing, that organizations are offering more choices in variety, speed, and also locational aspects (spacing) from the safety consideration of their customers. As a result, various markets are already or would be saturated through overcapacity from multiple players who are striving for low-cost efficiencies and quality in managing this new need. The problem is compounded by lowering of demand at least for the short term due to the economic downturn triggered by the pandemic. However, it implies that firms have to simultaneously compete on costs through value engineering, excellence through quality, and the choice trinity through flexibility in their capacities.

Hence they are under intense pressure to find novel ways to differentiate themselves for value creation by enhancing efficiency, improve quality, and offer flexibility all at the same time as depicted by the intersection in Exhibit. 1.0. The common area arising out of the intersection depicts the flexibility mix. It is the dynamic equilibrium between the capacities of the organization to maintain control, such as usage of technology & management systems to avoid drift into a chaotic state, as well as the managerial capabilities for creativity through people.

This paradigm shift is needed more now than ever to manage the paradox of handling change while maintaining organizational stability. It is imperative to generate a dynamic response to the rapid competitive changes arising from multiple competitors in an unpredictable environmental condition such as the current pandemic crisis. Hence the challenge facing our leaders today is to decode the required flexibility mix and act proactively for building the managerial capabilities and organizational capacities to maintain the agility. This shall in turn create a resilient and robust organization, that can quickly be transformed into a state of dynamic control to counter change and sustain excellence. Hence leaders must invest not only in technologies but also by recognizing that people are going to be the dominant factor in an organization responsible for managing change. It has been shown repeatedly that human ingenuity that can be systematically developed, is the only ultimate source for strategic innovation. It has to be nurtured by an enabling leadership-driven culture which is wholesome and resilient, to stand the test of times.

***